Engine packaging to blame for Fisker Karma garage fire? [UPDATE]

“The engine is shoehorned into that bay, because they had to use a larger engine, because it was too heavy a car,” Bereisa told AN. “As a result, there’s no room for exhaust routing and heat shielding to route the heat away.”

The Karma uses a turbocharged, 2.0-liter four-cylinder engine sourced from GM. In the Karma, however, the Ecotec does not drive the wheels, but acts as a generator to supplement and recharge the batteries. The report says that a fluid leak, combined with tight engine compartment confines and the resultant high heat from the gasoline engine’s exhaust and the would have been enough to cause the fire.

Fisker is maintaining that it is not the car’s battery pack that is at fault, and has pointed to other potential sources of the blaze, according to the report, telling AN that, “There are myriad combustible materials that could be in the garage, in the wheel arch, or picked up on the roadside.”

UPDATE: Fisker has released an official statement regarding this story. Scroll down to read it.

Anaheim, CA – May 11, 2012

Fisker Automotive has noted unfounded allegations, reported in the media, about the engine compartment layout of its Karma model. The manufacturer of the world’s first extended range luxury electric vehicle has received full technical and safety certification for all systems developed and installed in the Karma. That certification followed extreme testing of the vehicle, involving laboratory simulations of thermal incidents and on-the-road tests in extreme climate conditions. No incidents of any kind involving engine systems were found.

Paul Boskovitch, Director of Powertrain & Engineering of Fisker Automotive, said: “Our technologies and engine design have been fully tested and certified at the highest level. It is irresponsible and ill-informed for technology pundits to suggest otherwise in order to secure media attention for unfounded claims.”

Background: The Karma under-hood thermal environment was designed using the latest Computational Fluid Dynamic (CFD) software packages. Evaluations of the results were performed both by the Fisker Thermal team and external consultants.

Testing involved thorough road and lab exercises, including multiple hot weather trips over thousands of miles of incident-free operation in Death Valley and Palm Springs, CA. Additional testing was also performed successfully at maximum and sustained speeds (125mph/201km/hr) on the Autobahn in Germany.

In addition to road-use testing, further wind tunnel testing was completed at test Labs in the USA. These tests were run specifically to simulate the most difficult of conditions, those observed in the Middle East (GCC) and Africa.

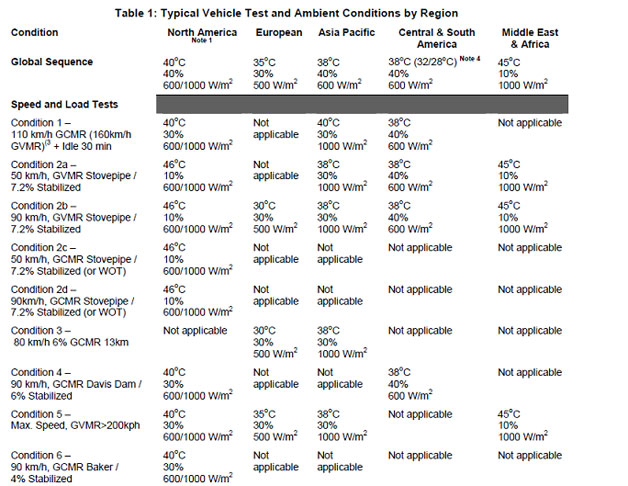

Testing for these hot weather conditions was run according to the manufacturer’s engine specifications for the 2-liter Ecotec engine installed in the Karma. The attached Table shows the conditions for typical vehicle tests by region. As indicated, the tests adopted for the Fisker Karma were conducted under the most stringent applications for the Middle East & Africa.

The Fisker Karma passed all tests without incident.

Cooling algorithms have been developed to ensure that at power off and under certain conditions the vehicle cooling fan maintains circulation in the engine compartment in order to remove any excess heat.

Packaging of the engine and surrounding components has been done within competitive benchmark standards and heat protection sleeves are placed on and around all hoses in or near high heat zones. All exhaust components have properly engineered heat shields and maintain the recommended separation distance between the shield, shielded components and affected components.

Fisker is using DEX-COOL 50/50 coolant with a zero flammability rating, according to the Chevron Manufacturers Safety Data Sheet (MSDS) #10445. This means that under no conditions is this material flammable.

The brake system booster which contains the brake system fluid is in a protected region behind the fender on the “cold” side of the engine. The power steering pump and fluid are also located on the “cold” side of the engine, near the front of the vehicle.

All materials used in the underhood environment are rated for use in the engine compartment and are either non-flammable or flame-retardant.

Operation of the engine on-cycle has been thoroughly explained in public literature and utilizes a load-following operation. During this operation acceleration events are augmented by the battery and the engine operates along the load curves at or less than would be observed during operation in its original design application. In the Karma application the engine is never required to operate beyond 3500 RPM with a maximum output capability of 128 kW at this operating point. Well below the rated power of this engine with a maximum output power of 194 kW.

The Fisker Karma is an advanced technology vehicle and utilizes a control strategy that focuses on fuel efficiency as well as thermal and energy management. The engine power required at 125 mph (top speed) is less than 115 kW, well below the maximum capability of the engine for continuous operation. In addition the engine controls maintain a thermal watch of the engine and at a temperature of 117C begins to limit power in order to maintain coolant temperature below this point. This is well below the engine manufacturer’s recommended maximum temperature rating of 127C.